Contact us now for your demand[email protected]

- Products

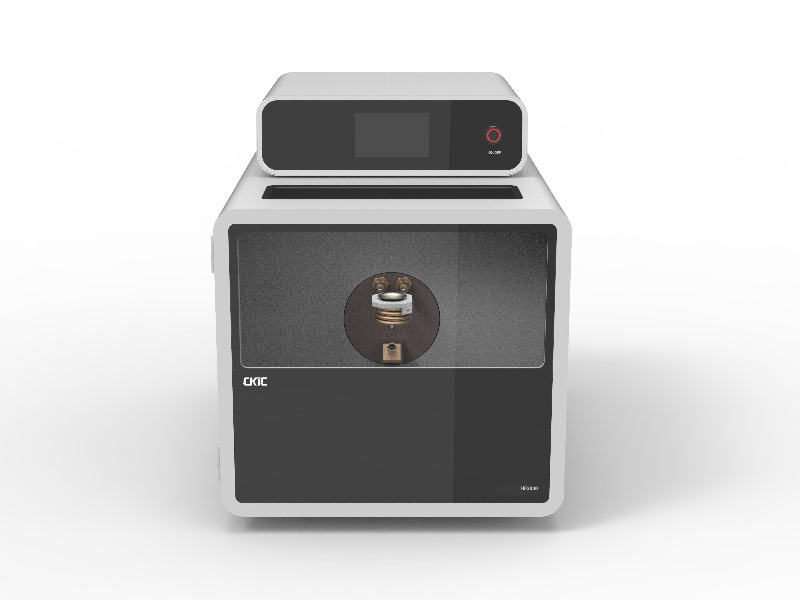

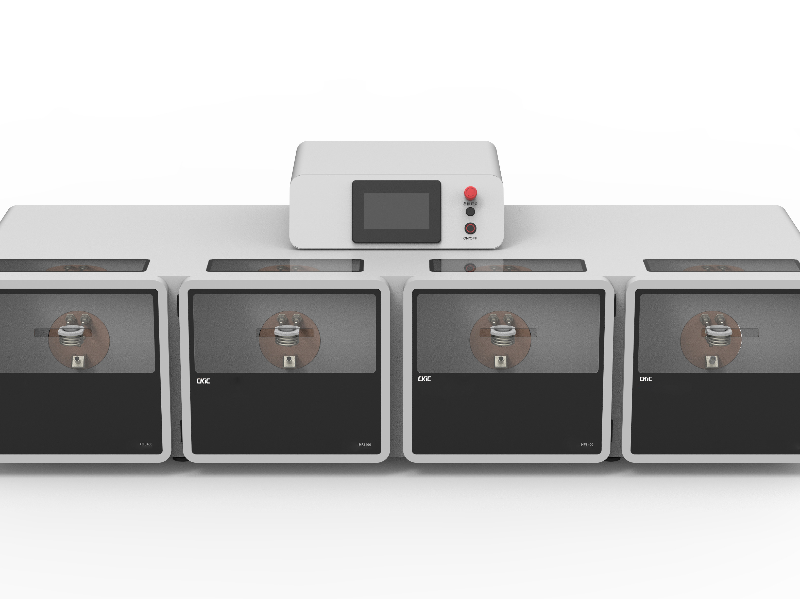

- Calorimeter

- Elemental Analyzer

- 5E-S32 Series Sulfur AnalyzerNEW!

- 5E Series C/H/N Elemental Analyzer

- 5E-TCN2200 Nitrogen/Protein Analyzer

- 5E-IRS3600 Automatic Infrared Sulfur Analyzer

- 5E-IRSII Infrared Sulfur Analyzer

- 5E-CS3800 Sulfur Carbon Analyzer

- 5E-CS3700 Inorganic Carbon Sulfur Analyzer

- 5E Series Fluorine/Chlorine Analyzer

- 5E-DMA Series Direct Mercury Analyzer

- 5E-AA2288 Automatic Cadmium Analyzer

- EDXRF Spectrometer & Pretreatment

- Proximate Analyzer

- 5E-TGA67 Series Proximate Analyzer-TGAPre Sales!

- 5E-MAG6700 Proximate Analyzer - TGA

- 5E-MAC6710 Proximate Analyzer - TGA

- 5E-MACIV Proximate Analyzer - TGA

- 5E-MVC6700 Automatic Volatile Matter Analyzer

- 5E Series Muffle Furnace

- 5E-MW6513 Automatic Moisture Analyzer

- 5E-MIN6150 Mini Moisture Oven

- 5E Series Drying Oven

- 5E-MW Series Automatic Moisture Analyzer

- TGM226 Automatic Moisture Analyzer

- 5E-MA27 Series Automatic Moisture and Ash Analyzer

- Ash Fusion Determinator

- Coking Coal Indices Determinator

- Hardgrove Grindability Index Tester

- Sample Preparation Equipment

- 5E-SDCSIII Dust-Removing System

- 5E-PA Series Sample Preparation Combination Apparatus

- 5E-APS Automatic Sample Preparation System

- 5E-HCB Series Hammer Crusher

- 5E-HCA400×260 Humid Coal Hammer Crusher

- 5E-JCA Series Jaw Crusher

- 5E-DCA250×150 Double Roller Crusher

- 5E-PCM Series Pulverizer

- 5E Series Sample Divider

- 5E-SSB200 Sieving Shaker

- 5E Series Assisting Tools

- Mechanical Sampler

- Management System

- Robotic Intelligent Laboratory System

- spare parts

- Application

- news

- support

- company

- contact

_340x255.png)